Group Site

(in Japanese)

(in Japanese)

(in Japanese)

Prometech Simulation Conference(PSC)

(in Japanese)

Prometech Group Recruiting Site

(in Japanese)

(in Japanese)

(in Japanese)

(in Japanese)

Prometech Simulation Conference(PSC)

(in Japanese)

Prometech Group Recruiting Site

(in Japanese)

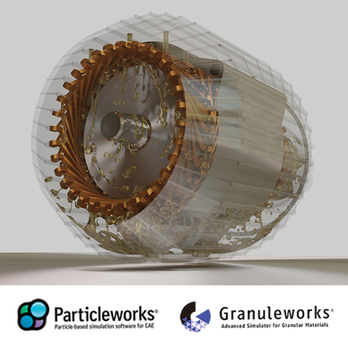

Prometech Software, Inc. (CEO: Toshimitsu Fujisawa, Head Office: Tokyo, hereinafter Prometech) has released the particle-based simulation software “Particleworks Ver. 8.0.0” and the granular materials simulation software “Granuleworks Ver.3.0.0”.

Particleworks is a CFD simulation software based on MPS -moving particle simulation- method. By using particles as calculation points without mesh generation, it greatly reduces the number of pre-processing steps such as simulation model creation and simulates complicated liquid behaviors including large-scale deformation of free surfaces such as oil behavior of power train, piston oil cooling, vehicles driving into the flooded road, mixing of food, chemicals and resin, debris and concrete flow, and tsunami runup, etc. Because of such simulation capabilities, Particleworks has been attracting attention in various fields including automotive, machinery, electric, material, food, chemical, biomedical, energy, and civil engineering industries all over the world.

Granuleworks is a granular material simulation software based on the discrete element method (DEM) theory. It can be used for manufacturing processes using powders, powder processing, and design and improvement of powder equipment for various fields including food, pharmaceuticals, chemicals, transport equipment, and electronic materials. Besides, by coupling with Particleworks, it can also simulate bubbles’ behavior in liquid.

【 New capabilities of Particleworks 】

■Multi-resolution

This method divides the simulation domain into the Coarse domain and the Fine domain, which are computed using coarse and fine particles, respectively. By only placing fine particles in areas that require high resolution or are narrow, it is possible to reduce computational load and memory consumption.

■MPFI

MPFI is a method that simultaneously calculates the pressure and viscosity terms of the Navier-Stokes equations implicitly without separating them. This method is effective for problems with low Reynolds numbers and high pressure, such as the flow of high-viscosity fluids like resins.

■Snow model

We provide the modeling of snow as a Bingham fluid (a fluid that does not flow until it is subjected to a certain shear stress). This allows for calculations such as snow compaction behavior, where snow is deposited and compressed.

第1回

(69分)

流体の支配方程式

支配方程式とは?/支配方程式を解くための準備/保存法則/連続の式/ナビエ・ストークス方程式/エネルギー式/圧縮/非圧縮性流体の支配方程式の違い/支配方程式の利用法

第2回

(76分)

非圧縮性流体の力学

非圧縮性流体とは?/流量の連続/ベルヌーイの定理/運動量法則/境界層流とは?/

境界層厚さの定義/層流境界層と乱流境界層/境界層のはく離/境界層方程式/

第3回

(71分)

圧縮性流体の力学

圧縮性流体とは?/流量の連続/ベルヌーイの定理/等エントロピー流れ/衝撃波とは?/垂直衝撃波/斜め衝撃波/衝撃波・境界層干渉

1時間目

(76分)

標準的な粒子法とその発展的方法

1. 標準的な粒子法(支配方程式、離散化、アルゴリズム、境界条件)

2. 圧力計算の発展的方法(要会報、圧力振動抑制)

3. 粘性計算の発展的方法(陰解法、非ニュートン流体)

4. 壁境界条件の発展的方法(ポリゴン壁境界条件)

2時間目

(48分)

粒子法を使いこなすための知識

1. 時間刻み幅の決め方(クーラン数、拡散数、数値安定性、計算精度)

2. 乱流の計算方法

3. 温度場の計算方法

トピックス1: 高精度粒子法(LSMPS法)

3時間目

(49分)

粒子法における様々な計算モデル

1. 表面張力モデル(CSFモデル、ポテンシャルモデル、濡れ性)

2. 空気抵抗モデル(有限体積法との連成)

3. 剛体モデル(DEMとの連成)

トピックス2: 可変解像度

4時間目

(69分)

シミュレーションの信頼性を高める方法論

1. V&V(Verification and Validation)とは

2. モデルV&V

3. 品質V&V

4. シミュレーションの品質向上活動(最近の状況)

トピックス3: 津波の大規模シミュレーション

1時間目

(58分)

粒子法による流体解析の基礎理論(その1)

粒子法の特徴と利点/粒子法の種類/粒子法の質量/粒子の位置と速度の初期設定/粒子の動かし方/加速度の求め方/支配方程式

2時間目

(96分)

粒子法による流体解析の基礎理論(その2)

粒子数密度と重み関数/偏微分演算子の近似方法/圧力の求め方/境界条件(自由表面、壁面、流入・流出 等)/物理モデルの紹介(粘性力、表面張力、剛体・流体連成、負圧 等)/検証事例の紹介

3時間目

(57分)

粒子法による流体解析の基礎理論(その3)、粒子法のソースコードの解説

ソースコードのコンパイルと実行(演習)/計算結果の可視化(演習)/シミュレーションプログラムの概説/プログラムの詳細解説(グランディエントモデル、ラプラシアンモデル 等)/パラメーターの設定方法/よくあるトラブルとその対処方法